TELELIN INSTRUMENTS INDIA

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to TELELIN INSTRUMENTS INDIA

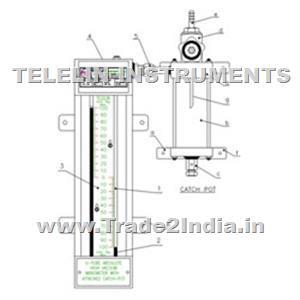

Dead Weight Pressure Gauge Tester

Dead Weight Pressure Gauge Tester provided with a gauge connector of 1/2" BSP and complete with one set of weights (MS Phosphated Black or SS 304) in a storage box, 1 dust cover, 1 instruction manual, 1 tin of oil (1/2 litre) and a tool box containing 1 pointer puller, 1 pointer punch, adapters of M20 x 1.5, 1/4" & 3/8" BSP, 4 Spanners, 1 Allan key, 1 screw driver and 1 set of spare seals. Accuracy ± 0.1% of F.S.

Important Explanation :

"BASIC PRICE" includes one set of weights (MS Phosphated Black) in any one unit of calibration i.e., kgf/cm 2 , bar, lbf/in 2 , mmHg or in Hg. If 2 units of calibration are required with one tester, order 1 extra set of weights that time itself. Similarly for 3 units of calibration, order 2 extra sets of weights. If unit of calibration is not specified, Instruments will be supplied in kgf/cm 2 unit for pressure testers and mm. Hg. for vacuum tester. Master gauges, High Accuracy Pressure Gauges will be supplied at extra cost.

REGULAR MODELS AND INC (SPECIAL) MODELS NO. AND RANGE DETAILS

|

Mode

|

|

RANGE (kgf/cm 2 )

|

||

|

|

Minimum Pressure

|

Smallest Step

|

Maximum Pressure

|

|

|

DW 10

|

|

0.1

|

0.01

|

2.5

|

|

DW 10-INC

|

|

0.1

|

0.001

|

2.5

|

|

DW 11

|

|

0.1

|

0.05

|

6

|

|

DW 11-INC

|

|

0.1

|

0.001

|

6

|

|

DW 12

|

|

0.2

|

0.05

|

16

|

|

DW 12-INC

|

|

0.2

|

0.002

|

16

|

|

DW 13

|

|

0.4

|

0.1

|

25

|

|

DW 13-INC

|

|

0.4

|

0.005

|

25

|

|

DW 14

|

|

0.4

|

0.1

|

40

|

|

DW 14-INC

|

|

0.4

|

0.005

|

40

|

|

DW 15

|

|

1

|

0.1

|

60

|

|

DW 15-INC

|

|

1

|

0.01

|

60

|

|

DW 16

|

|

1

|

0.1

|

100

|

|

DW 16-INC

|

|

1

|

0.02

|

100

|

|

DW 21

|

|

2.0

|

0.5

|

160

|

|

DW 21-INC

|

|

2

|

0.02

|

160

|

|

DW 22

|

|

4.0

|

1.00

|

250

|

|

DW 22-INC

|

|

4

|

0.05

|

400

|

|

DW 23

|

|

5.0

|

1.00

|

400

|

|

DW 23-INC

|

|

5

|

0.05

|

400

|

|

DW 24

|

|

10.0

|

2.00

|

600

|

|

DW 24-INC

|

|

10

|

0.1

|

600

|

|

DW 25

|

|

10.0

|

2.00

|

700

|

|

DW 25-INC

|

|

10

|

0.1

|

700

|

|

DE 26

|

|

10

|

2

|

1000

|

|

DW 26-INC

|

|

10

|

0.1

|

1000

|

|

DW 30

|

LP

|

0.2

|

0.10

|

16

|

|

|

HP

|

10

|

1

|

160

|

|

DW 30-INC

|

|

0.2

|

0.002

|

16

|

|

|

|

10

|

0.02

|

160

|

|

DW 31

|

LP

|

0.4

|

0.10

|

25

|

|

|

HP

|

24

|

1

|

250

|

|

DW 31-INC

|

|

0.4

|

0.005

|

25

|

|

|

|

24

|

0.05

|

250

|

|

DW 32

|

LP

|

0.4

|

0.10

|

40

|

|

|

HP

|

34

|

1

|

400

|

|

DW 32-INC

|

|

0.4

|

0.005

|

40

|

|

|

|

34

|

0.05

|

400

|

|

DW 33

|

LP

|

1.0

|

0.20

|

55

|

|

|

HP

|

50

|

2

|

600

|

|

DW 33-INC

|

|

1

|

0.01

|

55

|

|

|

|

50

|

0.1

|

600

|

|

DW-34

|

LP

|

1.0

|

0.20

|

65

|

|

|

HP

|

50

|

2

|

700

|

|

DW 34-INC

|

|

1

|

0.01

|

65

|

|

|

|

50

|

0.1

|

700

|

|

DW 35

|

LP

|

1.0

|

0.2

|

100

|

|

|

HP

|

50

|

2

|

1000

|

|

DW 35-INC

|

|

1

|

0.01

|

100

|

|

|

|

50

|

0.1

|

1000

|

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.